PI(S):

Sponsor(s):

Together with UNC Charlotte, we have built a magnetically-suspended stage designed to achieve 0.1-nm resolution, 1-nm repeatability, and 10-nm accuracy over a macroscopic range of 25 mm in X,Y and 100 microns in Z. To complete the project, we are currently developing an atomic force microscope head to allow accurate characterization of the performance of the LORS stage. This probe senses tip-sample separation using a miniature piezoelectric quartz tuning fork. When driven with an AC voltage at its resonant frequency and with a sharp tip mounted to one end, this sensor can resolve topographic features on the atomic scale. Development of integrated metrology with the inherent accuracy of the system remains one of the key design challenges. Scanned probe microscopy typically relies on open-loop control of PZT actuators, which may introduce errors due to hysteresis. Our design will incorporate closed-loop positioning of a PZT tube, thereby improving the probe's accuracy.

Atomic Force Microscope Probe with Metrology, for Subatomic Measuring Machine

Acknowledgments

This project is funded by National Science Foundation under Grant award number DMI-9821003

Motivation

In collaboration with the University of North Carolina at Charlotte, we have developed a magnetically-suspended stage designed to achieve 0.1-nm resolution, 1-nm repeatability, and 10-nm accuracy over a macroscopic range of 25 mm in X,Y and 100 microns in Z. A commercial scanning tunneling microscope (STM) was used for initial characterization of this LORS (LOng Range Scanning) stage, but did not perform satisfactorily. As is common with commercial STM's, the probe scanned the surface using a piezoelectric tube scanner operating in an open loop. The associated hysterisis and drift contributed to unacceptably large measurement errors. Additionally, the probe's platinum-iridium tips tended to wear over several repeated scans.

Figure 1: The LORS stage.

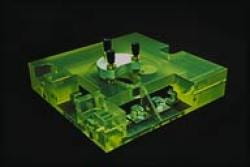

Figure 2: Zerodur metrology frame, with STM head.

Development of the stage continues. Current efforts at UNC-Charlotte to remove observed coherent Angstrom-scale oscillations should bring the stage's performance to its full potential. Concurrently, we have begun the design of a metrology atomic force microscope (AFM) head with the inherent accuracy of the system.

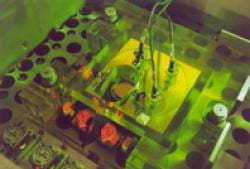

Figure 3: Inside the SAMM.

Description

AFM's have assumed a prominent role in the characterization of sample topographies on the atomic scale. As with other forms of scanned probe microscopy (SPM), AFM's provide orders-of-magnitude improvements in resolution over diffraction-limited optical methods. In practice, the AFM gains advantage over a number of other popular SPM techniques with its greater flexibility. Scanning tunneling microscopes, for instance, can only image samples with conductive surfaces, a restriction not applicable to AFM's.

Our design incorporates closed-loop control of a piezoelectric tube scanner, which guides a z-position sensor over the surface of the sample. We will use a miniature piezoelectric quartz tuning fork as the sensing element. As shown in various experimental studies, such a tuning fork may be used to detect atomic-scale surface features. In operation, we electrically excite the fork at its resonant frequency (2^15 Hz). When brought within roughly 10nm of the sample, near-surface atomic forces mechanically damp the fork's oscillations, altering the fork's electrical characteristics. While scanning in the X-Y plane, we will adjust the tube scanner's driving voltage to maintain a fixed fork impedance, thereby establishing a constant tip-sample separation. To create a topographic image of the sample, we simply record the relative extension or contraction of the scanner at each X-Y sampling point. To close the loop on the scanner, the head assembly will include a set of three capacitive gauges.